Liquid Roof is a liquefied version of a synthetic rubber typically referred to as EPDM. The letters EPDM stand for ethylene, propylene, diene monomer and M class. Unlike ordinary coatings liquid RV roof repair coatings have more uses as they can be used on RV roofs and other vehicles as well. Liquid RV Roof repair coatings can be applied to a wide range of roofing materials including metal, fiberglass and wood (although wood is not a warrantied application and require the use of the ProFlex primer first).

Application and Curing Process

This is a one coat system for

your RV which results in you saving labor costs and material costs since many ordinary

coatings on the market require multiple coats and provide no warranty. Before

the application of Liquid RV Roof be sure to clean the RV roof so that any oils

or fats are removed as they will cause the existing EPDM roof to swell. To

clean the RV roof you may wish to consider adding 2 cups of bleach to kill any

surface mold/mildew along with a standard detergent such as dawn dish washing

detergent or Simple Green. Let the RV roof to dry.

Liquid RV Roof is a DIY product.

You don’t need professionals to apply Liquid Roof as you can take care of the

entire project on your own. It can be easily

applied with a squeegee and a roller and a 24 ft. unit should take you approx.

two hours to apply. Note that once you mix the catalyst you have approximately

a 3-4 hour pot life depending on your daytime temperatures. The higher the

temperature the less pot life you have.

Liquid Roof normally takes about

two days above 50 degrees for the material to develop a skin and then 7 days

for a full cure. The higher your daytime temperature goes the quicker the

material will dry. If you get an unexpected rain no need to worry. Also in the

event of that unexpected shower the product is already waterproofed.

Cost and Value

Liquid RV Roof repair coating is

a one coat system for your RV which results you saving material and labor

costs. The money saved can be invested to remodel the RV interior. The best way

to apply the product is to chalk off the area into 42 square foot sections.

When you are done filling in that area, you should be done with a gallon of the

material. It also comes with 10 year warranty as well which gives you the value

for the money.

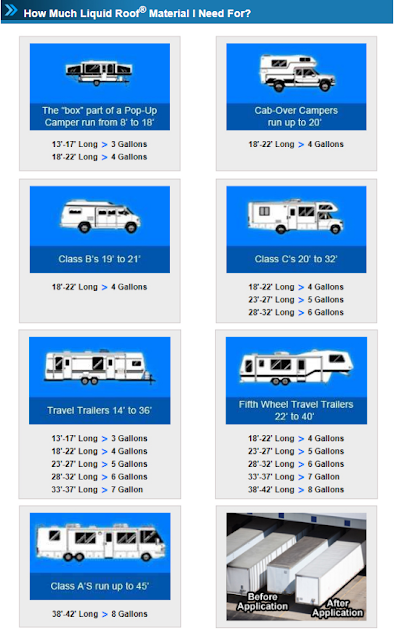

If you are still unsure how much

material e.g. Liquid RV Roof you need to recoat your RV, read carefully this

info graphic.

Pot Life of Liquid RV Roof

Once you mix the catalyst you

have approximately a 3-4 hour pot life depending on your daytime temperatures.

The higher the temperature the less pot life you have.

Pros and Cons

Features/Pros

ü Can

be applied over various roofing systems

ü UV

and Ozone resistant

ü Protection

against water ponding

ü Waterproofs

immediately

ü One

coat application

ü Hold

up extremely well to weather conditions

Cons

Most disadvantages of Liquid RV

Roof repair coatings are due to the improper installation or lack of

maintenance.

ü Requires

proper curing

ü Schedule

inspections and maintenance is required

ü Re-coating

needed

ü Not

a great insulator.

ü Need a primer for some roofs.

To Sum Up for You

Whether you have noticed a leak or not or want to reseal the RV as a part of routine maintenance, the Liquid RV roof repair coatings can be a fantastic investment for your RV. Having the coating will ensure you do not have to worry about leaking, or damage from UV rays any more. It is a nice solution all around and provides 360 degree protection to your RV roof.

Have any question? Call

855-281-0940 or visit https://www.rvliquidroof.net/

to shop Liquid RV Roof and prepare your RV for the next RV roof Repair project.

No comments:

Post a Comment